RESEARCH ARTICLE

Study of Cyclic Fracturing in Vertical CBM Wells

Ting Li1, 2, 3, Ji-fang Wan4, *

Article Information

Identifiers and Pagination:

Year: 2017Volume: 10

First Page: 108

Last Page: 117

Publisher Id: TOPEJ-10-108

DOI: 10.2174/1874834101710010108

Article History:

Received Date: 05/01/2017Revision Received Date: 05/03/2017

Acceptance Date: 16/03/2017

Electronic publication date: 28/04/2017

Collection year: 2017

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Background:

Coal-bed methane productivity of single well is very low, and has been the bottleneck of the coal-bed methane industry in China.

Objective:

Although hydraulic fracturing is the only stimulation measure to develop CBM, it cannot increase production effectively, conventional fracturing method to create opening fractures should be improved. How to make good use of natural fractures, which are plentiful in CBM reservoirs, is also an important subject for hydraulic fracturing.

Method:

In this paper, the plastic deformation of coal rock is analyzed by harnessing a pseudo-Maxwell creep phenomenon, which is normally present in rock. The Kelvin-Voigt model is utilized to describe pseudo-plastic behavior of coal rock to determine pressurization and decay cyclic time for cyclic fracturing design. The mechanical requirement for shearing natural fractures is also analyzed, and shearing distance between the faces of natural fracture can be calculated by Westergaard stress function. Ultimately, the cyclic fracturing method is proposed according to theories about stress alteration and shearing of natural fractures. This method includes such periods as fracturing, pumping shut-down and so on.

Conclusion:

A complex fracture system can be created, which consists of opened and sheared fractures, then, large SRV(stimulated reservoir volume)and flowing drainage area can be acquired. In comparison with conventional fracturing method, this new way can make full use of the characteristics of CBM reservoirs and is more suitable to CBM. This method will lead to a significant increase of CBM production, and will achieve huge economic benefits.

1. INTRODUCTION

In China, vertical wells have been applied in coalbed methane (CBM) development more than 20 years, and systematic technique has been formed, but low productivity of single well has been the restrained bottleneck for CBM industry [1-5]. Although hydraulic fracturing is the main stimulation approach for CBM reservoirs, in fact, the stimulation is not well effective. The increase of production for CBM wells depends on stimulated reservoir volume (SRV) and desorption rate of methane gas. In comparison with sand reservoirs, fractures are shorter and wider in CBM reservoirs, thus, the conventional fracturing technique should be improved to attain large SRV [6, 7]. Natural fractures and bedding planes are plenty in CBM, so how to take advantage of them is an important consideration in CBM fracturing.

Network fracturing technology applied in shale gas reservoirs has been successful, which changed the basic knowledge about conventional hydraulic fracturing and brought new visions for CBM fracturing [6-9]. Multidirectional fractures can be created in CBM, and have been testified by mine-back and other monitoring means, but this fact is hard to be accepted by many technical engineers, and they usually take measures to remove these multi-fractures to avoid sand screen-out. However, in order to increase SRV and flowing drainage area in CBM, the multi-fractures or complex fracture network should be created on purpose.

How to increase flowing drainage area as large as possible by hydraulic fracturing has been the desire for petroleum engineers. For example, Kiel proposed to create dendritic fractures using injection-hesitation method, which was applied in more than 400 wells effectively, and he also applied for patent [10-12]. But this method was not accepted by many engineers as valid in the industry, and they still believe bi-wing fracture theory with existence of multi-fractures in conventional fracturing. In the meanwhile, the quest for multifractures is still continuing. Warpinski discussed altered stress fracturing to pioneer the scientific foundation for multi-direction fracturing technology [13]. Moschovidis developed this technology and applied in Mounds-injection project to create fractures shifted from one to the next direction in the same well [14]. Surjaatmadja evolved this method from theory and experiments, and applied it together with hydra-jet fracturing in reservoirs [15-18]. Presently, the successful development of shale gas in North American has also proved the value of multidirection fracturing.

In this paper, an attempt is made to further exploit multidirectional fracturing technology to its utmost potential. Taking advantage of stress induced in the process of fracturing, and of shearing the natural fractures in CBM, complex fracture system will be created in comparison with the conventional fracturing method. And design method is also presented for increasing the productivity of CBM reservoirs.

2. THEORY FOR CYCLIC FRACTURING

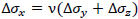

2.1. Calculation of Induced Stress

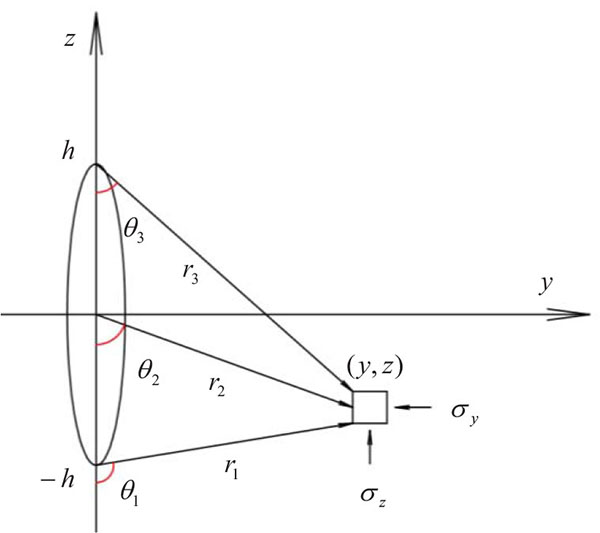

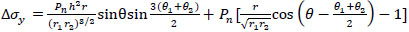

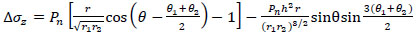

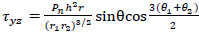

The net pressure in hydraulic fracture affects largely the around stress, especially in the direction of fracture cross section. If the fracture is longer, and the net pressure keeps almost same, which only changes at the fracture tip, and stress induced by the opening of hydraulic fracture is shown in Fig. (1).

|

Fig. (1). The stress induced by fracturing in the plane of Z-Y. |

According to the theory of Sneddon and Elliot, stress induced by long fracture in home-generous elastic solid can be calculated as follows [19, 20].

|

(1) |

|

(2) |

|

(3) |

|

(4) |

By use of the above equations, relationship between induced stress and distance from the fracture is demonstrated in Fig. (2). As can be seen, the induced stress at direction of minimum horizontal stress increases at the most, and at direction of maximal horizontal stress, the induced stress increases moderately. The induced stress decreases rapidly as the distance is increasing. When the distance is 3 times the half of fracture height, the induced stress changes little and keeps almost the same.

|

Fig. (2). The induced stress around hydraulic fracture. |

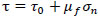

2.2. Shearing of Natural Fractures

There is a large amount of butt and face cleats in CBM reservoirs, so how to take advantage of these natural fractures is also an important issue. These fractures are closed initially, but if the stress condition is changed, they will slide (Fig. 3). Usually, they will slide easier than open, the shear mechanical limit will be discussed thereafter.

|

Fig. (3). The shearing of natural fractures. |

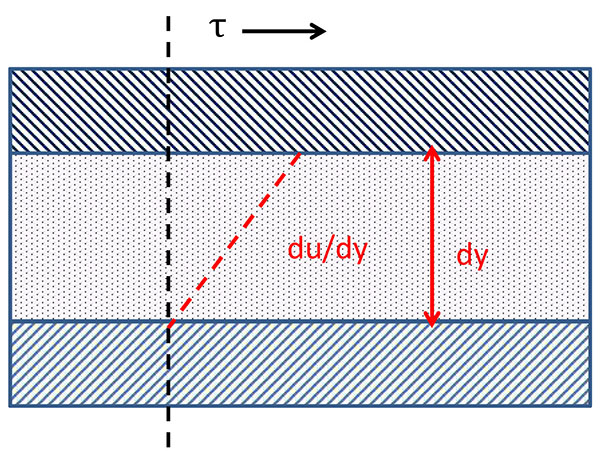

The shearing force acted on natural fracture can be calculated as follows [21].

|

(5) |

Some natural fractures are bonded with minerals, such as calciteor quartz, and if they are bonded well, therefore, fracturing fluid is difficult to enter into these fractures. But comparing with the coal matrix, the strength of natural fractures is lower, so Mode II or sliding fracture will be created crossed with the major fracture, which is opened during hydraulic fracturing treatment [22-25].If the force is substantial, the surfaces of natural fracture will shear like as stick slip, which is considered as dry friction motion (Fig. 4).

|

Fig. (4). Stick-slip between natural fractures. |

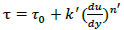

The shearing asperities are generally less than one micron in size, biting into each other’s surfaces. Since the coal rock is soft and deformed easily at a certain force, so it can be regarded as plastic solid. In this case, the use of Maxwell theory to rock viscosity can be justified, and a common Herschel-Bulkley fluid model is applied [26-29].

|

(6) |

These parameters, such as k' and n', can be determined by laboratory tests. Also, the upper stress limit and stick-slip stress can be acquired, which are used to define whether the shearing of natural fractures will happen or not.

The above equation is suitable for Newtonian motion similar to fluid, but for soft rock, the plastic motion is common, hence, the Kelvin-Voigt model is recommended for pseudo-plastic behavior [24].

|

(7) |

The equation describes the relationship with time t. If an initial stress is exerted to the rock, the deformation will approach the elastic model response with a difference that decays exponentially as follows.

|

(8) |

2.3. Relaxation Rate of Rock

Assume at time t1, the exerting stress disappears, the stress or deformation in rock will decay in an exponential manner [30-33].

|

(9) |

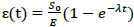

The stresses during the pressurization and decay (relaxation) can be plotted as shown in Fig. (5).

|

Fig. (5). Stress during the pressurization and decay [33]. |

Under different stresses, the weak plane or bedding will slide and initiate shearing fractures. The shearing fracture will follow the same stress buildup and relaxation curve as shown in Fig. (5). Therefore, composite stress chart will be observed as the stick-slip phenomenon. It means that different faces of natural fractures will shear or slide similarly, thus complex fractures will be created. Also, the hesitation between fracturing or pumping can be defined, if the pressurization and decay time is determined by experiments, thus, a cyclic time interval will be scheduled.

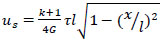

2.4. Shearing Length

The two faces of natural fracture will slide when shearing force is more than the upper limit, then, the shearing distance can be calculated according to the Westergaard stress function as follows.

|

(10) |

The maximum shearing distance is as follows.

|

(11) |

2.5. Permeability of Sheared Fractures

Assume that there are not proppants in sheared fractures, so the permeability can be calculated as follows [34, 35].

|

(12) |

If the width of sheared fracture is 10-4 m, porosity is 1%, the permeability of sheared fracture will be 8.33μm2. The permeability of coal matrix is usually at the level of 10-3μm2, obviously, the permeability of sheared fracture is far higher than the coal permeability, even the fracture width is in the scale of millimeter. When the sheared fracture is packed or sparsely by proppants, the width will be much larger, so the permeability will raise much. Therefore, the sheared fractures are important, and if they connect with each other to form fracture network, the production rate of CBM wells will rise significantly.

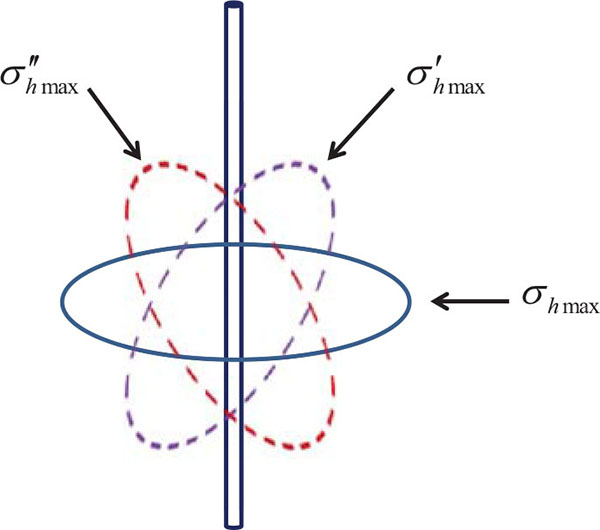

3. DESIGN OF CYCLIC FRACTURING

The objective of cyclic fracturing design is to create complex fractures and attain large SRV and drainage area. The design method should take full advantage of the characteristics, such as low elastic module and plenty natural fractures in CBM. Based on above theory about induced stress, the induced stress and change of in-situ horizontal stress can be calculated with different fracturing net pressure. In order to create fractures with different directions, fracturing net pressure will be designed and controlled during fracturing treatment. At the same time, shearing of natural fractures in CBM can be fulfilled by cyclic fracturing. Stress alteration is used to create major fractures with different extending directions, and natural fractures along with the hydraulic fractures are sheared to form complex fracture network, ultimately, the CBM reservoir will be stimulated thoroughly.

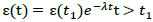

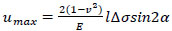

3.1. Application of Induced Stress

Fractures always extend perpendicular to the local minimum stress direction, and induces stress around nearby areas, which can be used to creat another fracture. The hydraulic fracturing period can be divided into different parts: first injection, stop and wait, then second injection and so on. Taking advantage of the stress alteration caused by the first hydraulic fracture and after a short delay, creating another fracture will be effective. If the the process is repeated several times, the stress alteration can be used to create fractures in multidirection (Fig. 6), therefore, the SRV and drainage will be larger than the bi-wing conventional fracturing method.

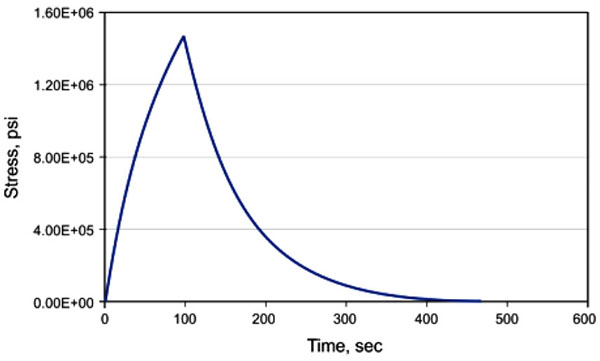

3.2. Shearing Natural Fractures

From above discussion, the direction of natural fractures is important for shearing, but the shearing also can be achieved when the rock around major hydraulic fractures is pressurized plastically, no matter whether the fracturing fluid enters the natural fractures or not. The coal rock is soft, and it is easy to deform in fracturing treatment, so the natural fractures will be sheared easier contrast with the hard rock. When the limit shear stress of natural fractures is determined in CBM reservoirs, the intent of shearing them can be fulfilled by adjusting the fracturing treatment pressure and schedule. Ultimately, a complex fracture system may be created with large SRV and flowing drainage area (Fig. 7).

|

Fig. (6). Multidirectional fractures caused by induced stress. |

|

Fig. (7). Multidirectional fractures in reservoir plane map of multidirectional fractures. |

4. FIELD CASE

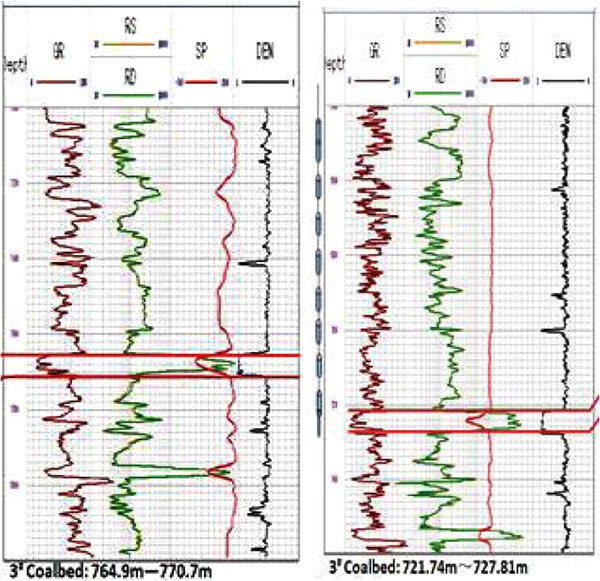

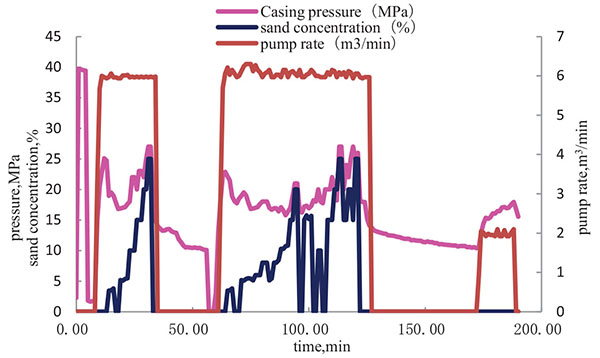

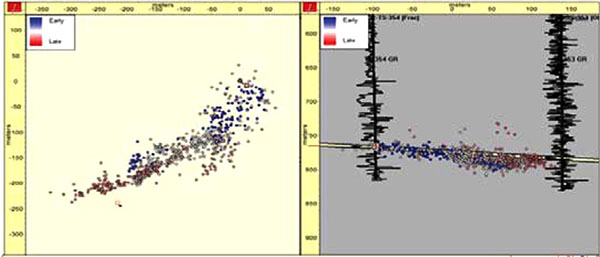

In Qinshui CBM basin, well No. QS 40-8 was fractured as above stimulation design theory and method. The treatment zone is shown in Fig. (8), and actual fracturing curve is Fig. (9). The fracturing process is divided into three cycles. In first cycle, after the fracture is opened, extended and connected, then pumping is shut down and the pressure is unloaded. After half an hour, fracturing treatment began again, and sand concentration was raised smoothly. When pressure rose drastically, sand pumping was stopped, and repeated several times. During the treatment, micro-seismic wave was monitoring in the nearby well No. QS 40-9, and the result (Fig. 10) showed that complex or network fractures were formed. The evaluation of the micro-seismic invasion demonstrated that the width of network fracture is 75 m, and the length is 420 m. Furthermore, the production rate testified that the fracturing result was better than the conventional method. After half five months later, the CBM production was nearly 4000 m3/d, which exceeded the average production by a factor of 4 (Fig. 11).

|

Fig. (8). The aimed zone of well No. QS 40-8The monitoring well QS 40-9. |

|

Fig. (9). The treatment curve of well No. QS 40-8. |

|

Fig. (10). The result of microseismic monitoring about well No. QS 40-8. |

|

Fig. (11). The production curve of well No. QS 40-8. |

CONCLUSION

- The local stress around fractures will be altered during the treatment of hydraulic fracturing. Taking advantage of this stress change, multidirectional fractures can be created on purpose, which is different from conventional hydraulic fracturing technology.

- Shearing the plenty natural fractures in CBM reservoirs is a creative method to form complex fractures or network fracture system. This method could take full use of the characteristics of CBM reservoirs, and has been testified by underground hydraulic fracturing for extracting CBM in coal mines.

- By combining altering stress with shearing natural fractures, the multidirectional fracturing method could stimulate the CBM reservoirs thoroughly, and will increase the SRV and drainage area drastically, so it is suitable to CBM reservoirs.

LIST OF ABBERIVIATIONS

| h | = half height of fracture,m |

| Pn | = net pressure in fracture,MPa |

| v | = Poisson’s ratio of rock |

| ∆σx, ∆σy, ∆σz | = the induced stress in the direction of x, y, z respectively,MPa |

| τyz | = induced shear stress in the plane of y-z,MPa |

| r | = distance between random point in reservoir and the midpoint of fracture,m |

| r1 | = distance between random point in reservoir and the bottom point of fracture,m |

| r2 | = distance between random point in reservoir and upper point of fracture,m |

| θ | = angle from the z axis to the line of random point in reservoir and midpoint of fracture,rad |

| θ2 | = angle from the z axis to the line of random point in reservoir and bottom point of fracture,rad |

| θ1 | = angle from the z axis to the line of random point in reservoir and upper point of fracture,rad |

| τ,τ0 | = shearing force between faces of natural fracture,MPa |

| μf | = friction factor |

| σn | = the net compressive pressure on the natural fracture,MPa |

| k', n' | = the index constant of Herschel-Bulkley model |

|

= shear deform rate, m/s |

| us | = shearing distance, m |

| l | = fracture length, m |

| x | = the point position along the fracture, m |

| k | = Kolosov constant |

| G | = shear module, MPa |

| umax | = the maximum shearing distance, m |

| S(t) | = shear stress, MPa |

| E | = Young’s modulus of elasticity, MPa |

| ε(t) | = the strain, m |

| μa | = the absolute viscosity of the rock |

| Kf | = permeability of sheared fractures, × 10-3μm2 |

| Øf | = porosity of fractures |

| Wf | = the width of sheared fracture, m |

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

The work is supported by the petroleum engineering college of Yangtze University and the Yangtze Youth Fund (2016cqn27: The research on casing damage mechanism of depleted gas storage)