RESEARCH ARTICLE

Effect of Mud Weight on Hole Cleaning During Oil and Gas Drilling Operations Effective Drilling Approach

Kevin C. Igwilo1, *, Emeka E. Okoro2, Princewill N. Ohia1, Solomon A. Adenubi2, Nnanna Okoli1, Temilade Adebayo1

Article Information

Identifiers and Pagination:

Year: 2019Volume: 12

First Page: 14

Last Page: 22

Publisher Id: TOPEJ-12-14

DOI: 10.2174/1874834101212010014

Article History:

Received Date: 12/12/2018Revision Received Date: 19/02/2019

Acceptance Date: 19/03/2019

Electronic publication date: 31/05/2019

Collection year: 2019

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Introduction:

A good hole cleaning operation is an important factor for every successful drilling program. Drilling mud should be formulated to suspend and transport cuttings effectively to minimize the number of drill cuttings in the hole. It is therefore, essential to determine the best weighing material that would be incorporated into the drilling mud for efficient hole cleaning given the well’s condition and formation type.

Methods:

This work is aimed to provide a detailed comparative analysis on the effect of drilling mud weight, using different concentrations of barite and calcium carbonate as weighing materials to determine optimum materials for hole cleaning.

Results and Discussion:

The results show that barite gave a lower annular pressure drop and therefore, a better Equivalent Circulating Density (ECD) compared to calcium carbonate, though, calcium carbonate gave better results in terms of transport efficiency and cutting concentration compared to barite.

Conclusion:

Barite is highly applicable in high-pressure reservoirs and calcium carbonate is applicable in depleted reservoirs. It can also serve as a bridging agent and can be used in reservoirs where it is necessary to minimize formation damage.

1. INTRODUCTION

The specific objective of this research is to ascertain the high gravity solids and low gravity solids that gives better hole cleaning during oil and gas drilling operations while the main objective is to measure the effect of mud weight in achieving effective hole cleaning of the wellbore.

The transportation of cuttings and good hole cleaning is very important in any drilling operation because a successful drilling operation is vital to a profitable business in the oil and gas sector. A successful drilling program is a product of an efficiently cleaned hole whereas, a poorly cleaned hole implies the accumulation of formation cuttings in the well [1]. This leads to a number of problems which include; Stuck pipe, increased cost of drilling, decreased rate of penetration, formation fracturing and many others. The basic function of a drilling fluid is the transportation of cuttings generated during drilling activities and this must be done effectively, with the hole being cleaned with a minimum accumulation of cuttings in the annulus. This will, therefore, prevent downtime during drilling operations and the costs will therefore, be optimized [2]. The ability of the operations to effectively remove drill cuttings dictates the efficiency of a drilling operation. Hence, the efficiency of the cutting removal and hole tidiness is a very vital requirement factor for meeting the desired drilling objective. Cuttings transport efficiency of a drilling program depends on a number of factors such as cuttings concentration, rate of penetration, fluid flow regime, hole geometry and inclination, and rheology amongst others. It is necessary to carry out analysis on drilling mud to determine their rheological properties, transport efficiency and all other factors that are necessary for a good hole cleaning operation [3].

Adari et al [4], arranged the parameters controlling cuttings transport in their order of relevance and from their illustration, fluid rheology, volumetric flow rate and rate of penetration have the highest control on the efficiency of hole cleaning. In horizontal wells, cuttings removal is easier with turbulent flow than laminar flow. As the angle of inclination of the well increases, the circulation time required to clean the wellbore increases [5]. Drilling cuttings, under the influence of gravity, tend to fall through the ascending drilling fluid. The velocity at which this tends to occur is known as the slip velocity. The fluid velocity must be high enough to overcome the slip velocity of the particles for effective cuttings removal [6]. A proper hole cleaning exercise is the efficient and effective transport of drilled solids from the wellbore to the surface. This helps with the reasonable unhindered movement of the tubular and drill strings [7]. A good understanding of the mechanics of cuttings transport is important for the optimization of drilling hydraulics for a hitch-free drilling [8].

Demirdal [9] compared theoretical frictional pressure losses with experimental data. Hydraulic diameter approach was employed for the Bingham Plastic Model, Power Law model and Yield Power Law model [10]. The final analysis indicated that calculated pressure losses overestimate the measured values in both laminar and turbulent flow conditions. Osei [11] noted that adequate cuttings removal from a well while drilling is critical for cost effective drilling, as high annular cuttings build up often leads to high risk of stuck pipe, reduced rate of penetration and other impediments to standard drilling and completion. The investigation was on the rheological parameters that influence the removal of cuttings in non-vertical boreholes. Micah [12] reiterated the importance of accurate estimation of annular pressure losses in drilling and well completion operations, and calculated the pressure loss gradients/ Equivalent Circulating Density (ECD) using annular frictional pressure equations as the basis of relating the results obtained from the rheological model- equivalent diameter definition combinations.

Unegbu [13] highlighted the various factors that affect the cuttings removal and made an attempt to develop a model to bridge the gap between existing models, of which a single model was proposed, and a chart was also developed. Jachnik [14] reported that flow properties are important for understanding hole cleaning and suspension characteristics. Iyoho and Zamora [15] noted that an increase in mud rheology can reduce ECD if the hole cleaning efficiency is simultaneously increased. Ochoa [16] carried out a study for selecting the rheological model that best fits the rheological properties of a given non-Newtonian fluid. Igwilo [17] noted that the most relevant function of a drilling fluid is the ability to carry drill cuttings from the bit up to the annulus to the surface. The study further explained that the rheology of the drilling fluids and the associated annular hydraulics is directly dependent on the hole cleaning efficiency; and canvassed for adequate understanding of rheology as essential for cost effectiveness in meeting the drilling objective. Also, Okarjni and Azar [18] carried out a study on the effects of field-measured mud rheological properties on cuttings transport. They observed that the annular mud velocity in vertical well drilling must be sufficient to avoid cuttings settling and assist in transporting these cuttings to the surface in a reasonable time. Azar and Sanchez [19], in their study, made an interesting review on the factors that affect cuttings transport. They highlighted drilling fluid rheology, drill string rotation, drilling rates, flow rate and annular eccentricity, among others. The density of drilling mud has an associated effect on carrying capacity [20].

1.1. Basis of the Research

Two weighting materials were used in the analysis to observe the effects on the identified factors as annular pressure loss, cuttings transport efficiency and cuttings concentration that influence hole cleaning. The reason for using barite and calcium carbonate as two different materials is to affect the efficiency of hole cleaning by looking at the increase in the magnitude of plastic viscosity of the drilling mud system. Plastic viscosity is the measure of the quantity and quality of solids present in the mud. Plastic viscosity is the function of mud weight. Increase in mud weight increases the plastic viscosity of the mud. Plastic viscosity is inversely proportional to the Reynolds number. Therefore, optimising the mud weight and the plastic viscosity improves the hole cleaning by putting the system into laminar flow.

Also, in this research, both low gravity solids such as calcium carbonate of an average specific gravity of 2.6 and high gravity solids such as barite of an average specific gravity of 4.2 were considered. Sand formation and shale formation were used to represent solids to be cleaned during oil and gas drilling operations. The groundwater is being controlled by the drilling mud already treated with a fluid loss control additive.

2. METHODOLOGY

This section is divided into three parts, namely: (a) Mud formulation (b) Mud weights and Rheological properties measurements (c) Evaluation of annular pressure drop, cutting concentration and transport efficiency.

2.1. List of Apparatus

Apparatus used were weighing balance, measuring cylinder, beakers, Hamilton beach mixer, mud cup, mud balance, six point fann viscometer with thermostat.

2.2. Mud Formulation

The mud was formulated as shown in Table 1 without weighting material and with calcium carbonate and barite as weighting materials as shown in Tables 2 and 3, respectively. Also included in the formulations were different additives to carry out specific functions.

| Mud Weight | PPG | Mud Type | |||||

|---|---|---|---|---|---|---|---|

| Product Name | Mixing Order & Time | Brand Name | Product Specific Gravity | Product Concentration Field Barrel | Product Concentration Lab Barrel | ||

| Mins | Lbs/Bbl | Gals/Bbl | Grams | Mils | |||

| WATER | 0 | Water | 1 | 251.00 | - | 251.00 | 342.94 |

| Viscosifier 2 | 2 | - | 1.5 | 1.50 | - | 1.50 | 1.00 |

| Fluid loss Additive 1 | 1 | LV | 2 | 0.15 | - | 1.25 | 1.25 |

| Alkalinity | - | Soda Ash | 2.5 | 0.25 | - | 0.25 | 0.10 |

| NACL | 2 | NACL | 3.31 | 14.54 | - | 14.54 | 4.37 |

| Other | 1 | Caustic Soda | 2.13 | 0.25 | - | 0.25 | 0.12 |

| Other | 2 | X-CIDE 102 | 1.07 | 0.25 | - | 0.25 | 0.23 |

| - | 350.01 | ||||||

| Mud Weight | PPG | Mud Type | |||||

|---|---|---|---|---|---|---|---|

| Product Name | Mixing Order & Time | Brand Name | Product Specific Gravity | Product Concentration Field Barrel | Product Concentration Lab Barrel | ||

| Mins | Lbs/Bbl | Gals/Bbl | Grams | Mils | |||

| WATER | 0 | Water | 1 | 331.00 | - | 331.00 | 331.83 |

| Viscosifier 2 | 2 | - | 1.5 | 1.50 | - | 1.50 | 1.00 |

| Fluid loss Additive 1 | 1 | HV | 2 | 0.15 | - | 1.25 | 1.25 |

| Alkalinity | - | Soda Ash | 2.5 | 0.25 | - | 0.25 | 0.10 |

| NACL | 2 | NACL | 3.31 | 14.54 | - | 14.54 | 4.37 |

| Other | 2 | CaCO3 | 2.7 | 30.00 | - | 30.00 | 11.11 |

| Other | 1 | Caustic Soda | 2.13 | 0.25 | - | 0.25 | 0.12 |

| Other | 2 | X-CIDE 102 | 1.07 | 0.25 | - | 0.25 | 0.23 |

| - | 350.01 | ||||||

| Mud Weight | PPG | Mud Type | |||||

|---|---|---|---|---|---|---|---|

| Product Name | Mixing Order & Time | Brand Name | Product Specific Gravity | Product Concentration Field Barrel | Product Concentration Lab Barrel | ||

| Mins | Lbs/Bbl | Gals/Bbl | Grams | Mils | |||

| WATER | 0 | Water | 1 | 251.00 | - | 251.00 | 324.13 |

| Viscosifier 2 | 2 | - | 1.5 | 1.50 | - | 1.50 | 1.00 |

| Fluid loss Additive 1 | 1 | HV | 2 | 0.15 | - | 1.25 | 1.25 |

| Alkalinity | - | Soda Ash | 2.5 | 0.25 | - | 0.25 | 0.10 |

| NACL | 2 | NACL | 3.31 | 14.54 | - | 14.54 | 4.37 |

| Other | 2 | CaCO3 | 2.7 | 10.00 | - | 30.00 | 11.11 |

| Other | 1 | Caustic Soda | 2.13 | 0.25 | - | 0.25 | 0.12 |

| Other | 2 | X-CIDE 102 | 1.07 | 0.25 | - | 0.25 | 0.23 |

| BARITE | 2 | BARITE LOCAL | 3.9 | 60.00 | - | 30.00 | 7.69 |

| - | 350.00 | ||||||

| Mud Properties | 0ppb | 30ppb | 60ppb | 90ppb | 120ppb |

|---|---|---|---|---|---|

| Mud Weight, ppg | 8.7 | 9.1 | 9.4 | 10.2 | 10.7 |

| Plastic Viscosity, cp | 11 | 15 | 21 | 22 | 30 |

| Yield Point, lb/100ft2 | 34 | 32 | 32 | 42 | 46 |

| 10 Second Gel, lb/100ft2 | 25 | 21 | 28 | 31 | 43 |

| 10 Min Gel, lb/100ft2 | 49 | 43 | 49 | 62 | 78 |

| Yield Stress, lb/100ft2 | 11 | 10 | 18 | 19 | 26 |

| 600 RPM | 56 | 62 | 74 | 86 | 106 |

| 300 RPM | 45 | 47 | 53 | 64 | 76 |

| 200 RPM | 39 | 42 | 47 | 51 | 65 |

| 100 RPM | 28 | 30 | 34 | 39 | 43 |

| 6 RPM | 19 | 20 | 26 | 29 | 38 |

| 3 RPM | 15 | 15 | 22 | 24 | 32 |

| Mud Properties | 0ppb | 30ppb | 60ppb | 90ppb | 120ppb |

|---|---|---|---|---|---|

| Mud Weight, ppg | 8.7 | 9.5 | 9.9 | 10.6 | 11 |

| Plastic Viscosity, cp | 11 | 13 | 21 | 22 | 31 |

| Yield Point, lb/100ft2 | 34 | 30 | 27 | 40 | 34 |

| 10 Second Gel, lb/100ft2 | 25 | 17 | 22 | 31 | 35 |

| 10 Min Gel, lb/100ft2 | 49 | 36 | 41 | 62 | 69 |

| Yield Stress, lb/100ft2 | 11 | 9 | 15 | 18 | 23 |

| 600 RPM | 56 | 56 | 69 | 80 | 96 |

| 300 RPM | 45 | 43 | 48 | 58 | 65 |

| 200 RPM | 39 | 37 | 42 | 46 | 56 |

| 100 RPM | 28 | 27 | 31 | 37 | 41 |

| 6 RPM | 19 | 15 | 21 | 26 | 33 |

| 3 RPM | 15 | 12 | 18 | 22 | 28 |

| True Vertical Depth | 2056ft |

| Length of Casing | 2156ft |

| Length of Drill Pipe | 2074ft |

| Length of Drill Collar | 150ft |

| Diameter of Drill Pipe | 5.5in |

| Diameter of Hole | 16in |

| Diameter of Drill Collar | 7.785in |

2.3. Mud Weight and Rheology Measurements

The fann viscometer readings at different dial speeds of 600rpm, 300rpm, 200rpm, 100rpm, 6rpm, 3rpm were obtained using VG meter at 120OF. The mud weight at different concentrations using barite and calcium carbonate respectively was also measured at 120OF as shown in Tables 4 and 5.

2.4. Evaluation of Pressure Drop, Cutting Concentration and Transport Efficiency

The research involved the evaluation of annular pressure loss, cuttings transport efficiency and cuttings concentration of drilling mud using calcium carbonate and barite as weighting materials. The drilling mud was formulated with different concentrations of barite and calcium carbonate (Tables 1-3). Rheological properties of the drilling mud were determined in the laboratory using a rotational viscometer and a mud balance at API standard (API RP 13B-1). The annular pressure drop, cutting concentration and the transport efficiency were evaluated on an excel spreadsheet using the rheological data from Tables 4 and 5 and the field data in Table 6. The results of this computation are tabulated in (Tables 7a and 7d) and (Tables 8a and 8b), respectively. The evaluation is based on Modified Power law principle using the rheological data.

| - | Calcium Carbonate in Shale Formation | - | |

|---|---|---|---|

| Concentration of Caco3(ppg) | Density of Mud (ppg) | Transport Efficiency (%) | Cutting Concentration(% Vol.) |

| 0 | 8.7 | 72.19177836 | 1.207432377 |

| 30 | 9.1 | 73.05002502 | 1.193246553 |

| 60 | 9.4 | 78.61642 | 1.108759348 |

| 90 | 10.2 | 80.90794908 | 1.077356324 |

| 120 | 10.7 | 84.29464524 | 1.034071504 |

| - | Calcium Carbonate in Sandstone Formation | - | |

|---|---|---|---|

| Concentration of Caco3 | Density of Mud (ppg) | Transport Efficiency (%) | Cutting Concentration(% Vol.) |

| 0 | 8.7 | 46.63740113 | 1.869029758 |

| 30 | 9.1 | 48.28433394 | 1.805278927 |

| 60 | 9.4 | 58.96596997 | 1.478254163 |

| 90 | 10.2 | 63.36330068 | 1.375665245 |

| 120 | 10.7 | 69.86220274 | 1.247694564 |

| - | Barite in Shale Formation | - | |

|---|---|---|---|

| Concentration of Caco3 | Density of Mud (ppg) | Transport Efficiency (%) | Cutting Concentration(% Vol.) |

| 0 | 8.7 | 72.19177836 | 1.207432377 |

| 30 | 9.5 | 70.60060559 | 1.234645083 |

| 60 | 9.9 | 77.26749333 | 1.128115936 |

| 90 | 10.6 | 80.73809284 | 1.079622858 |

| 120 | 11 | 83.63071926 | 1.042280771 |

| - | Barite in Sandstone Formation | - | |

|---|---|---|---|

| Concentration of Caco3 | Density of mud (ppg) | Transport Efficiency (%) | Cutting Concentration (% Vol.) |

| 0 | 8.7 | 46.63740113 | 1.869029758 |

| 30 | 9.5 | 43.58401946 | 1.999969063 |

| 60 | 9.9 | 56.37744657 | 1.546126969 |

| 90 | 10.6 | 63.03735499 | 1.382778363 |

| 120 | 11 | 68.58816169 | 1.27087078 |

| - | 0ppb | 30ppb | 60ppb | 90ppb | 120ppb |

|---|---|---|---|---|---|

| Herschel-Bulkley principle (∆p) psi | 11.037 | 10.052 | 18.018 | 19.032 | 26.009 |

| - | 0ppb | 30ppb | 60ppb | 90ppb | 120ppb |

|---|---|---|---|---|---|

| Herschel-Bulkley principle (∆p) psi | 10.052 | 9.037 | 15.02 | 18.026 | 23.016 |

The following assumptions were made:

- The annular flow behind the outer diameter of the drill collar is turbulent.

- The annular flow behind the outer diameter of the drill pipe is laminar.

The following equations were used to make calculations for this analysis:

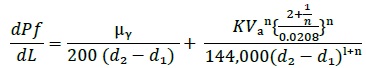

3. ANNULAR PRESSURE DROP EQUATION

Based on the Modified power law principle, Pressure loss is given by:

|

(1) |

Where, Va = Annular velocity in ft/sec

d1, d2= Hydraulic diameter, inches

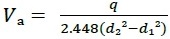

Other related formulas from i to vii [21]:

|

(2) |

Where Va= Annular velocity in ft/sec

q = Flow Rate in gpm

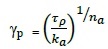

|

(3) |

Where γp= Shear rate in s-1

ka= Annular consistency index

na= Annular flow behaviour index

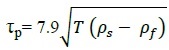

|

(4) |

Where τp= Shear stress

T = Cutting thickness in inches.

|

(5) |

Where γp = Shear rate in s-1.

Vs = Cuttings slip velocity in ft/s.

dp = Diameter of the drill pipe in inches.

|

(6) |

Where Tr= Cuttings Transport Ratio

|

(7) |

Where Tc= Cuttings Transport Efficiency

|

(8) |

Where Ca = Cuttings Concentration in vol. %

ROP = Rate of Penetration in ft/hr.

4. RESULTS AND DISCUSSION

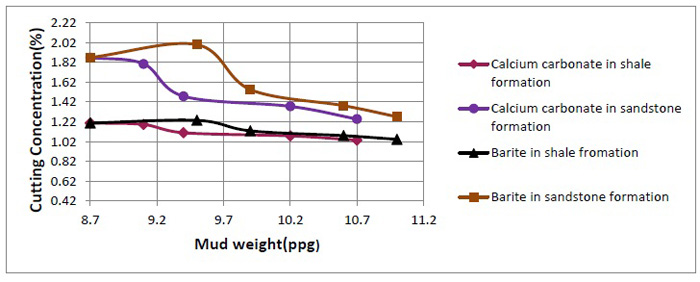

The results from the calculations of annular pressure drop, cuttings transport efficiency and cutting concentration are presented in Fig. (1). A good hole cleaning procedure practically depends on the type of weighting material used and the practice applied during the drilling operation. This analysis involves the use of barite and calcium carbonate as weighting materials. The fresh mud was prepared using both weighting materials. Fig. (1) shows the effect of the weighting materials on annular pressure drop. A sample of barite 4.2 SG and calcium carbonate 2.7 SG was used to carry out the laboratory tests. Both weighting materials from the plots gave good results but barite gave a better result. From the plots, at a mud weight of 8.7ppg, calcium carbonate gave a pressure drop of 11.037psi while barite gave a lower pressure drop of 10.052 psi. This trend continued for both weighting materials at subsequent mud weights. Barite gave a low annular pressure drop which would result in a better ECD and better hole cleaning operation.

Fig. (2) shows the effect of the weighting materials on transport efficiency in shale and sandstone formations. Calcium carbonate gave a higher transport efficiency result compared to barite in both formations. This result is backed up by the findings of Kippax and Ward-Smith (2013) who explained that calcium carbonate has finer particles compared to barite after careful analysis using a master sizer 2000 from Malvern instruments and a laser diffraction analyser. They further explained that fine particles are usually associated with high viscosities that promote the suspension and transportation of cuttings. This accounts for the high transport efficiency given by calcium carbonate in both shale and sandstone formations.

|

Fig. (1). Effect of weighting materials on annular pressure drop. |

|

Fig.(2). Effect of weighting materials on transport efficiency in shale and sandstone formations. |

|

Fig. (3). Effect of weighting materials on cutting concentration in shale and sandstone formations. |

| Criteria | Weighting Material | Reference |

|---|---|---|

| Low pressure drop | Barite | Fig. (1) |

| Improved ECD | Barite | Fig. (1) |

| Improved flow efficiency | Calcium carbonate | Fig. (2) |

| Improved cutting concentration | Calcium carbonate | Fig. (3) |

| Applicable in depleted reservoirs | Calcium carbonate | Fig. (3) |

It is also evident from Fig. (2) that shale formation has higher transport efficiency than sandstone formation with both weighting materials. Cuttings size slightly influences hole cleaning. According to the work of Larsen et al (1993), small particles are more difficult to clean than larger particles. This is because smaller particles form more compact beddings compared to bigger particles that form loose compact beddings which can be easily swept away. Sandstone has more loose and unconsolidated particles compared to shale. Shale has a larger cutting size this is why it gives a better transport efficiency.

Fig. (3) shows the effect of weighting materials on cutting concentration in shale and sandstone formations. From the plots, calcium carbonate gave a better result than barite in both formations. A low cutting concentration is ideal for a good hole cleaning procedure. This is because of the high transport efficiency already portrayed by Calcium carbonate because of its fine particles as observed by Kippax and Ward-Smith (2013) so there tends to be lesser amount of drill cuttings when calcium carbonate is incorporated into the drilling mud than when barite is used. As a result of this, calcium carbonate is applicable in depleted reservoirs (low pressure reservoirs) and it can act as a bridging agent. It also minimizes formation damage.

It is also evident from Fig. (3) that shale gives a lower and better cutting concentration using both weighting materials compared to sandstone. The higher the transport efficiency, as already explained above from Fig. (2), the lower the cutting concentration. High cutting concentration would lead to high ECD and higher chances of hole cleaning issues. The summary of the selection criteria based on the analysed results for both weighting materials is shown in Table 9.

5. PUBLIC INTEREST STATEMENT

Cuttings transport with emphasis on hole cleaning is a subject of interest in the Exploration and Production (E&P) industry, because inefficient cuttings transport or wellbore cleaning leads to differential sticking and formation fracture if not controlled. Drilling fluid properties have been identified as important factors in achieving efficient wellbore cleaning. These properties are both rheological and mud weight properties. The rheological properties include yield point, low shear rate yield point, and qualitative plastic viscosity, but in this study, the emphasis is on drilling mud weight as related to hole cleaning was investigated. Two field applicable weighting agents of barite and calcium carbonate were used for these analyses, and their individual results were analysed with respect to the aim of the study.

CONCLUSION

The following conclusions were derived from this study:

- Drilling mud weighted up with barite gave a better annular pressure drop than the drilling mud weighted up with calcium carbonate.

- Calcium carbonate gave a better result in terms of cutting concentration compared to barite in both shale and sandstone formations.

- Calcium carbonate gave a better cutting transport efficiency compared to barite in both shale and sandstone formations.

- Shale gave a better transport efficiency and cutting concentration for both weighting materials.

- The higher density weighting material gave a better hole cleaning result than the lower density weighting material

NOMENCLATURE

| ECD | Equivalent Circulating Density |

| API | American Petroleum Institute |

| Va | Annular Velocity, ft/sec |

| d1, d2 | Hydraulic Diameter, inches |

| q | Flow Rate, gpm |

| γp | Shear Rate, S-1 |

| ka | Annular Consistency Index |

| na | Annular Flow Behaviour Index |

| T | Cutting Thickness, Inches |

| Vs | Cuttings Slip Velocity, ft/s |

| dp | Diameter of the Drill Pipe, Inches |

| Tr | Cuttings Transport Ratio |

| Tc | Cuttings Transport Efficiency |

| Ca | Cuttings Concentration, Vol. % |

| ROP | Rate of Penetration, ft/hr |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

A specific grant from funding agencies in the public, commercial, or not-for-profit sectors was not received for this research work.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.

REFERENCES

| [1] | Adenubi AS, Igwilo KC, Okoro EE, Mamudu AO. Data for analyzing drilling fluid ability to effectively achieve hole cleaning for high shear and low shear rates. Data Brief 2018; 19: 1515-21. |

| [2] | Okoro EE, Dosunmu A, Iyuke SE. Data on cost analysis of drilling mud displacement during drilling operation. Data Brief 2018; 19: 535-41. |

| [3] | Ekeinde EB, Okoro EE, Dosunmu A, Iyuke S. Optimizing aqueous drilling mud system viscosity with green additives. J Pet Explor Prod Technol |

| [4] | Adari RB, Miska S, Kuru E, Bern P, Saasen A. Selecting Drilling Fluid Properties and Flow rates for Effective Hole Cleaning in High angle and Horizontal wells SPE Annual Technical Conference and Exhibition 1-4.Dallas. 2000; pp. 2000; |

| [5] | Busahmin B, Saeid NH, Hassan UHBH, Alusta G. “Analysis of Hole Cleaning for a vertical Well”, Open Access Library Journal 2017; Vol. 4 e 3579: 2333-9721. |

| [6] | Noah AZ. Optimizing Drilling Fluid Properties and Flow Rates for Effective Hole Cleaning at High Angle and Horizontal Wells. J Appl Sci Res 2013; 705-18. |

| [7] | Ofesi SF, Onwukwe SI, Duru UI. Optimizing hole cleaning using low viscosity drilling fluid 2017; 51-61. |

| [8] | Wang K, Yan T, Sun X, Shao S, Luan Shizhu S. Review and analysis of cuttings transport in complex structural wells. Open Fuels Energy Sci J 2013; 6: 9-17. |

| [9] | Demirdal B. The Study of Flow of Paraffin Based Synthetic Based Drilling Fluid at Elevated Pressure and Elevated Temperature (EPET) conditions Tulsa, Oklahoma, USA2001. |

| [10] | Demirdal B, Stefan ZB, Nicholas ET, Cunha JC. Drilling fluids rheological and volumetric characterization under down hole conditions Buenos Aires, Argentina2007. |

| [11] | Osei H. A Review of the Rheological Effects of Power Law Drilling Fluids on Cutting Transportation in Non-Vertical Boreholes 2009. |

| [12] | Micah EM. Combined Effect of rheological model and Equivalent Diameter Definitions on Pressure Losses/Equivalent Circulating Density estimation Abuja1-63.2011; |

| [13] | Unegbu C. Hole Cleaning and Hydraulics 2010; 1-75. |

| [14] | Jachnik RP. Low Shear Rate Rheology of Drilling Fluids Annual Transactions of the Nordic Rheology Society, Vol. 11, 2003 Available from: https://nordicrheologysociety.org/Content/ Transactions/2003/Richard |

| [15] | Iyoho AW, Zamora M, Aldea C. Hole cleaning: The Achilles’ Heel of Drilling Performance 2005. |

| [16] | Ochoa MV. Analysis of drilling fluid rheology and tool joint effect to reduce errors in hydraulics calculations 2006. |

| [17] | Igwilo KC. Fundamentals of Drilling Fluids Technology.Choba 2000. |

| [18] | Okrajni SS, Azar JJ. The effects of mud rheology on annular hole cleaning in directional wells. SPE Drill Eng 1986; 1(40): 297-308. |

| [19] | Azar JJ, Sanchez RA. Important issues in Cuttings Transport for Drilling Directional Wells 1997. |

| [20] | Salehi M M, Malekzadeh N. Optimization of Hole Cleaning and Cutting Removal in Vertical, Deviated and Horizontal Wells In Society of Petroleum Engineers SPE Asia Pacific Oil and Gas Conference and Exhibition, 20-22 September, Jakarta, Indonesia, 2011 |

| [21] | Baker Hughes Inteq. Drilling Fluids Manual 1999; 10-, 22, 36, 48,180. |