RESEARCH ARTICLE

Research of Network Fracturing Method for Coalbed Methane Reservoirs

Ting Li1, 2, Jifang Wan*, 3

Article Information

Identifiers and Pagination:

Year: 2016Volume: 9

First Page: 247

Last Page: 256

Publisher Id: TOPEJ-9-247

DOI: 10.2174/1874834101609010247

Article History:

Received Date: 01/01/2016Revision Received Date: 30/08/2016

Acceptance Date: 28/09/2016

Electronic publication date: 29/11/2016

Collection year: 2016

open-access license: This is an open access article licensed under the terms of the Creative Commons Attribution-Non-Commercial 4.0 International Public License (CC BY-NC 4.0) (https://creativecommons.org/licenses/by-nc/4.0/legalcode), which permits unrestricted, non-commercial use, distribution and reproduction in any medium, provided the work is properly cited.

Abstract

The application of conventional hydraulic fracture treatment is not ideal in coalbed methane reservoirs, which influences the industry development in China, thus, the present technique should be improved. From two aspects of net pressure and stress sensibility of permeability, it is analyzed and considered that permeability around hydraulic fractures is damaged severely, so this is the main flaw of conventional hydraulic fracturing in CBM. It is proposed to shear natural fractures by fracturing treatment, which are plentiful in coalbed methane reservoirs, and the mechanical condition to generate sheared fractures is presented, in the meanwhile, it is verified that the permeability of sheared fractures is much larger than coal matrix permeability. When the angle between natural and hydraulic fractures is small in coalbed methane reservoirs, the natural fractures will shear easily at low net pressure, so network fractures can be formed. In comparison with conventional hydraulic fracturing, this new methodology can make natural fractures shear at low net pressure to form transverse network fractures, hence, the stimulated reservoir volume is larger, and damage to coal permeability is avoided. This new technique is advantageous in both stimulated reservoir volume and permeability improvement, and it is more adaptable for coalbed methane reservoirs, thus, it has a wide application prospect and significant value.

1. INTRODUCTION

For several decades, coalbed methane (CBM) reservoirs have been developed commercially in U.S., and hydraulic fracturing has been used to accelerate removal of methane from coal seams of underground mines [1]. Along with the success of developing CBM in U.S., more and more CBM reservoirs are developed in different countries. Since 1994, CBM has been in production from 6 main coal seams in Bowen basin of Australia, which covers an area of about 1600 km2, and the permeability ranging from tens to a few hundred 10-3μm2 of the majority wells [2, 3]. In China, CBM development began at 1990’s, but the production results are not ideal compared with other areas of the world. The permeability of CBM reservoirs is very low, mostly in the range of 10-6-10-3μm2, and the reservoirs have to be fractured hydraulically before production [4-6] . The average production of single well is lower than 1000 m3 per day, which has a large gap from expected production and restricts the CBM industry development in China [7-9].

Hydraulic fracturing has been a key technology in developing CBM resources worldwide, but the appropriate technology will depend on the characteristics of the reservoir and the well operations. Since CBM reservoirs are complex, naturally fractured, dual-porosity systems, hydraulic fracturing in coal is more complex than in conventional reservoirs. It is important to focus on how to adequately connect the natural fracture system to the wellbore and maximize the stimulated reservoir volume [10]. CBM production data and stimulation experience have demonstrated that the linkage of the induced shydraulic fracture to a conductive natural fracture set is of key importance to well performance [11]. Although the hydraulic fracturing technique is effective in sand reservoirs, it is not able to work well in CBM reservoir, therefore, the conventional fracturing method should be improved to increase the stimulation results soundly based on CBM characteristics [12, 13].

In this paper, the permeability damage around hydraulic fractures is analyzed by correlations about net pressure and permeability stress sensibility, and it is regarded as the main flaw of conventional hydraulic fracturing in CBM reservoirs. There are plentiful natural fractures in CBM reservoirs, it is necessary to open and connect them with each other, hence, shearing these fractures to form complex fracture network is proposed, and the mechanical condition to generate sheared fractures is discussed. Finally, comparing the production yield per year of surface development with the underground mines in China, it is verified that the technology used in underground mines to produce CBM can generate fracture network, and it brings new insights for surface development of CBM.

2. REASONS FOR LOW PRODUCTION OF CBM IN CHINA

2.1. Different Reservoir Characteristics

Comparing the parameters in Table 1 [14], we can see that the average permeability of Qinshui basin is lower than other CBM basins, which resulted in the lower production. The geologic condition governs the producing ability of CBM reservoirs, and cannot be changed manly. What we can do is to make full use of the characteristics on the limited basis.

| CBM field | Ro (%) |

Depth (m) |

Average permeability /mD |

Methane content /m3/ton | Sorption saturation (%) |

Thickness (m) |

Formation pressure /MPa |

Gas production /m3d |

Water production / m3d |

|---|---|---|---|---|---|---|---|---|---|

| San Juan (USA) |

0.9- 1.2 |

100- 1000 |

>5 | 12 | 3-12 | 0.9-8.9 | 30 000 | 0-40 | |

| Alberta (Canada) |

0.5- 2.0 |

200- 700 |

10-500 | 1-5 | 70-97 | 4-10 | 1.8-6.3 | 3000 | 2 |

| Bowen (Australia) |

1.5 | 100- 600 |

0.1-10 | 0.98-5.88 | 90-100 | 5-12 | 0.9-5.4 | 6000-30 000 | 30 |

| Qinshui (China) |

2-4 | 300- 800 |

0.02-0.58 | 13-22 | 75-90 | 3.2- 8.6 |

1.8-4.8 | 1200 | 3 |

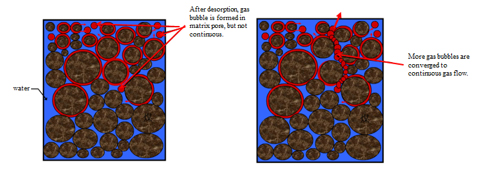

Coal is anisotropic and dual porosity water saturated reservoir mainly containing methane. Most of the methane molecules in coal seam are present in adsorbed state as a layer of gaseous molecules on the coal surface, and only a minor amount is available in a free state. Methane is produced by reduction in overall pressure of the reservoir, which is achieved by dewatering,and desorbed methane flows through the cleat system into wellbore (Fig. 1).

|

Fig. (1). Methane desorption process [15]. |

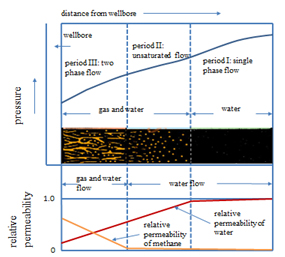

Gas production from CBM reservoirs is governed by complex interaction of single-phase gas diffusion through micro-pore system and two-phase gas and water flow through cleat/fracture system that is coupled through diffusion process [15]. The whole production period includes 4 key points: dewatering to lower pressure, desorption, diffusion and flowing in fractures (Fig. 2).

|

Fig. (2). Methane gas producing period [15]. |

The gas producing rate depends on the slowest one among the 4 key processes. Because most methane is adsorbed on coal surfaces, and formation water exists in natural cleats, so, the methane is difficult to desorb freely, which results in the speed of desorption and diffusion of methane in coal matrix is the lowest. At this condition, the process of desorption and diffusion will determine the CBM production rate.

From above analysis, how to increase the speed of methane desorption and diffusion becomes the key to raise CBM production of single well. There are two ways to increase production, one is to raise the flowing rate, which actually is the lowest speed among desorption, diffusion, and flowing in natural fractures, and the other is to increase flowing drainage volume.

2.2. Permeability Damage of Hydraulic Fracturing

In coal seam, the vast majority of the gas is stored in coal matrix, which practically has no permeability. The flow to production well, however, occurs through the coal’s natural fracture system, which stores relatively small amount of gas. In order to achieve commercially viable gas production rate, interventions are necessary to be taken in CBM reservoirs. Hydraulic fracturing technique is therefor used in CBM, but it is a double-edged sword. On one hand, the conventional hydraulic fracturing can increase the gas flowing speed by creating man-made fractures. On the other hand, it cannot increase desorption and diffusion speed, which is the key factor to raise production, and it will also damage the coal matrix permeability.

For CBM reservoirs, the elastic modulus is lower (compared with sand), and Poisson’s ratio is larger, which result in coal rock be fractured easily. The fractures formed in CBM are wider and shorter, and the stimulation result is not as good as in sand reservoirs. During the process of fracturing treatment, especially when a large amount of sand is pumped into fractures, the reservoir around the fractures will be stressed severely, and the coal permeability is too sensitive to stress, so the coal permeability will be reduced extremely.

Based on the theory of linear elastic mechanics, the fracture width is proportional to net pressure in the fracture.

|

(1) |

The coal permeability is sensitive to stress, and the relationship concluded by a lot of experiments is as follows [16].

|

(2) |

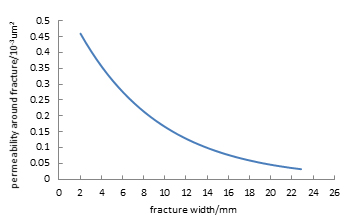

According to Table 2 [17], assume Young’s modulus of coal is 5000 MPa, Poisson’s ratio is 0.25, fracture height is 25 m, the initial permeability is 0.46 × 10-3μm2, the pore compressibility coefficient 0.16 MPa-1. The fracture net pressure and permeability can be calculated by equation (1), (2) with different fracture width.

From Fig. (3), if net pressure increases from 1.0MPa to 5.5MPa, the fracture width will increase from 2.0 mm to 20 mm. In Fig. (4), when the fracture width increases from 2.0 mm to 20 mm, the matrix permeability will decrease from 0.45 × 10-3μm2 to 0.05 × 10-3 μm2, thus the damage around fracture is very severe. Since the coal rock is soft and the elastic modulus is low, the fracture width is normally more than 20 mm generated in fracturing treatment. The damage will be more severe, especially when more sands are pumped to prop the fractures fully. Because the permeability damage is difficult to recover during gas producing period, so it is the main reason that stimulation effect is not ideal in CBM.

| Rock type | Young’s modulus/GPa | Poisson’s ratio | Rock type | Young’s modulus/GPa | Poisson’s ratio |

|---|---|---|---|---|---|

| mud stone | 2.84 | 0.28 | tight sandstone | 7.02 | 0.21 |

| coal | 0.4-0.8 | 0.22-0.33 | limestone | 6.74 | 0.23 |

| fine sandstone | 5.82 | 0.25 |

|

Fig. (3). Effect of different fracture width on net pressure. |

|

Fig. (4). Effect of different fracture width on coal permeability around fracture. |

3. NEW HYDRAULIC FRACTURING METHODOLOG

3.1. Mechanical Analysis of Network Fracturing

The coal matrix permeability is low, but the natural fractures, such as butt and face cleats, are plenty in CBM reservoirs. How to make use of these natural fractures is an important issue. The conventional fracturing technique just considers how to open fractures, but do not focus on how to shear existing natural fractures and connect them with each other. For CBM reservoirs, the natural fractures should be treated properly. The micro-seismic monitoring results have shown that sheared and complex fractures are generated during fracturing treatments in CBM reservoirs [18-21]. Therefore, the mechanical condition for shearing fractures will be analyzed to provide foundation for network fracturing in CBM.

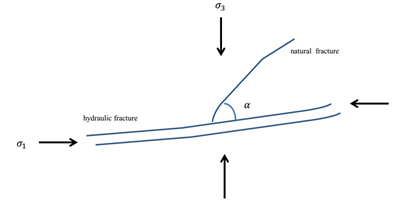

3.2. Mechanical Requirements for Shearing Fractures

During the treatment of hydraulic fracturing, the vertical fracture always propagates perpendicular to the minimum horizontal in situ stress. The direction of natural fractures is in an angle with the maximum horizontal stress (Fig. 5). When hydraulic fracture is near to natural fracture, the pressure of hydraulic fracture is higher, in the meaning while, the permeability of natural fracture is larger than the coal matrix’s, so the fracturing fluid will enter into the natural fracture firstly, and lead to pressure increasing continuously. The natural fractures are close under initial reservoir condition, when more and more fracturing fluid flow into them, the pressure will raise rapidly, which results in the shearing of natural fractures before opening.

|

Fig. (5). Relationship between natural and main fractures [22]. |

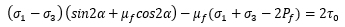

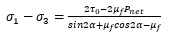

The shearing force acted on the natural fracture can be calculated as follows [22].

|

(3) |

The above equation can be transformed as follows.

|

(4) |

When the angle between natural and hydraulic fracture is determined, the force to shear natural fracture can be satisfied under known fracture net pressure.

|

(5) |

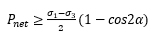

Hence, the fracture net pressure should satisfy the equation as follows.

|

(6) |

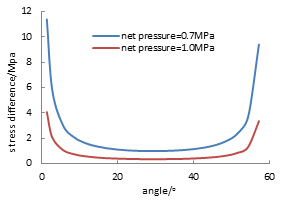

When friction factor is 0.6, and fracture net pressure is 0.7 MPa, the critical stress difference can be calculated under different angles. If treatment net pressure surpasses this value, the natural fracture will shear and slide. The angle between natural and hydraulic fracture impacts the critical net pressure greatly (Fig. 6). When the angle is larger than 60o, the critical net pressure will increase quickly. Under this condition, although the treating pressure raises much, it is difficult to shear the natural fracture. The direction of natural fractures is important for shearing, and it requires that the angle between natural and hydraulic fracture should be clarified before designing a proper treatment schedule.

The natural fractures will be opened if the fracturing net pressure is higher than the critical pressure and fracture closure pressure. In order to shear the natural fractures to generate fracture network, the fracturing net pressure should be controlled lower than the critical pressure during hydraulic fracturing treatment. After the network extends to a certain scope, the treatment pressure can be increased above the critical pressure to form a long main fracture, which connects the natural face and butt cleats to generate networks. Ideally, the fracture networks will stimulate the CBM reservoir fully and provide flowing drainage volume as large as possible [23-30]. Under lower net pressure, the damage around fractures can be avoided, and fracture networks can increase drainage volume obviously, thus, the methane producing rate will be raised greatly [31-35].

|

Fig. (6). Effect of angles between natural and main fractures on critical stress difference. |

3.3. Permeability of Sheared Fractures

Assume that there are not proppants in sheared fractures, so the permeability can be calculated as follows.

|

(7) |

If the width of sheared fracture is 10-4 m, porosity is 1%, the permeability of sheared fracture will be 8.33μm2. The permeability of coal matrix is usually at the level of 10-3μm2, obviously, the permeability of sheared fracture is far higher than the coal permeability, even the fracture width is in the scale of millimeter. When the sheared fracture is packed or sparsely by proppants, the width will be much larger, so the permeability will raise much. Therefore, the sheared fractures are important, and if they connect with each other to form fracture network, the production of CBM wells will rise significantly.

4. CASE HISTORY

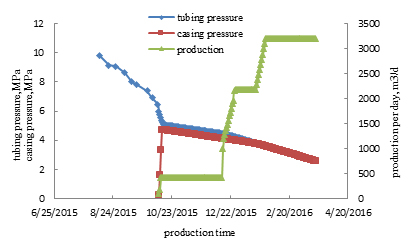

The above new fracturing methodology was applied in Qinshui CBM basin. The key of stimulation treatment is to control pumping pressure lower than fracture pressure at the beginning. When natural fractures are connected to form network fractures to a certain scale, then pumping pressure is increased to generate main fracture channel. At some distance around wellbore, network fractures are generated, hence, dewatering and desorbing rate will be raised, and higher methane production will be acquired eventually. The new fracturing methodology was tested on SZ 37-8 methane well, and half a year later, the CBM production was nearly 2000 m3/d. Ultimately, the production kept at 3200 m3/d, which exceeded the average production by a factor of 3.2 (Fig. 7).

|

Fig. (7). The production curve of SZ 37-8 well. |

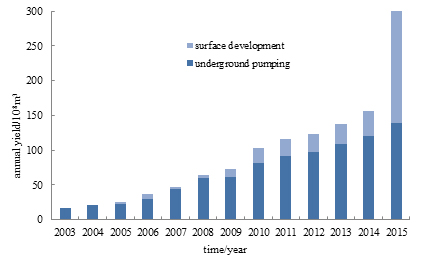

In China, as an effective increasing permeability technology for coal seam underground, drilling hydraulic fracturing has been widespread applied with good results, which can be confirmed by the production yield statistics (Fig. 8). The total production yield of CBM is 152 × 108m3 in 2014, and 36 × 108m3 is from the surface development, 116 × 10 8m3 from underground pumping of coal mines. Although underground fracturing is confined to the space and equipment ability,it is difficult to achieve large displacement or add proppant and crack is easy to closing, the mechanism of increasing coal permeability should be focused on. It shows that natural cracks could open, extend and connect to form fracture network during this underground treatment, and it also provides clues and new vision to improve conventional fracturing used in CBM reservoirs. On the other hand, it means that the technique to shear the natural fractures before opening them can be realized and feasible.

|

Fig. (8). CBM production yield in China. |

CONCLUSION

- The reasons are explained for lower production of CBM in China. Because most methane is adsorbed on the coal surface, and only a minor amount is free, and the production process includes 4 key points: dewatering to lower pressure, desorption, diffusion and flowing in fractures, so, gas production depends on the process of desorption and diffusion. In order to increase gas production, there are two ways: raise the flowing rate and increase flowing drainage volume.

- Hydraulic fracturing is a double-edged sword in CBM reservoirs. The application of conventional hydraulic fracturing technique is not ideal in CBM, and it is explained by theoretical calculation from the two aspects of induced stress and permeability sensitivity to stress.

- According to the characteristics that there are plenty natural fractures in CBM reservoirs, a new hydraulic fracturing technique is proposed to shear the natural fractures to generate fracture network, and this new methodology can avoid permeability damage and enlarge drainage volume. 4) The mechanical requirements and stimulation effect are presented in theory. If the angle between natural and hydraulic fractures is small, the natural fractures are easier to be sheared under lower net pressure, so network fractures can be formed in CBM reservoirs.

LIST OF ABBERIVIATIONS

| Δσ | = Fracture net pressure, MPa |

| W | = Fracture width, mm |

| ν | = Poisson’s ratio |

| H | = Fracture height, m |

| K 0 | = The initial permeability, ×10-3μm2 |

| K | = The permeability after stress changed, ×10-3μm2 |

| Cp | = The pore compressibility coefficient, MPa-1 |

| Δσp | = The stress difference, MPa |

| τ 0 | = The shearing force, MPa |

| μf | = Friction factor |

| σn | = Vertical stress on the natural fracture, MPa |

| σ1, σ3 | = The maximum and minimum horizontal stress, MPa |

| α | = The angle between natural and hydraulic fracture, |

| P f | = The extension pressure, MPa |

| Pnet | = Fracture net pressure,MPa, Pnet = Pf – σ3 |

| Kf | = Permeability of sheared fractures, × 10-3 μm2 |

| øf | = Porosity of fractures |

| Wf | = The width of sheared fracture, mm |

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

Declared none.