RESEARCH ARTICLE

Drilling Centers Maturity Model Evaluation Based on Integrated Operation Key Elements: A Case Study from Brazil

Claudio Benevenuto De Campos Lima1, 2, *, Vladimir Steffen Pinto2, Luis Gustavo Sobreira1, Rodrigo Nunes Ferreira2, Danilo Garbazza Vieira1, 2, Jose Francisco Tebaldi De Castro1, 2, Gilson Brito Alves Lima2

Article Information

Identifiers and Pagination:

Year: 2016Volume: 9

First Page: 313

Last Page: 323

Publisher Id: TOPEJ-9-313

DOI: 10.2174/1874834101609010313

Article History:

Received Date: 23/08/2016Revision Received Date: 04/11/2016

Acceptance Date: 10/11/2016

Electronic publication date: 30/12/2016

Collection year: 2016

open-access license: This is an open access article licensed under the terms of the Creative Commons Attribution-Non-Commercial 4.0 International Public License (CC BY-NC 4.0) (https://creativecommons.org/licenses/by-nc/4.0/legalcode), which permits unrestricted, non-commercial use, distribution and reproduction in any medium, provided the work is properly cited.

Abstract

The current economic situation is pushing the oil industry toward higher efficiency and safety, demanding different ways of work. Optimization is an increasingly important issue, which involves technology, sharing of real-time information, collaboration, and the application of multiple expertise across disciplines, organizations, and geographical locations. In this way, companies are introducing Integrated Operations to redesign and optimize many work processes. To address this challenging scenario, Petrobras, the Brazilian oil operator, decided to optimize the collaborative environments of its drilling centers which are critical for well construction, to introduce integration and improve efficiency. This article presents a methodological approach that is applicable across the oil industry, including a survey of drilling centers to document perceptions concerning the key Integrated Operations components: people, process, technology and organization. This approach applied an intensive assessment. The applicability and scalability of this methodology are reinforced by inclusion of statistical analysis of questionnaire responses. The study results were used to implement a unique collaborative environment that has decreased operating time and facilitated future operational improvements. The research pointed to positive impacts on both, the safety and performance aspects. The preliminary results are promising. For an example, it was observed a 7.25% decrease in time required for a casing run.

1. INTRODUCTION

High uncertainty in the price of oil is a significant problem for oil and gas companies [1]. The recent large decrease in price and consequently projected project revenue as well as postponement and cancellation of other investments has led to a dramatic reduction in the drilling rig fleet and implementation of cost-cutting initiatives worldwide [2]. These economic challenges for the oil and gas industry demand different ways of work. Integrated Operations (IO) is a new way of doing business. It is a concept used to describe the integration in the dimensions of people, process, technology and organization, to have better decisions in the right time. There is a variety of names related to IO in the oil industry [3].

After years of significant investment in IO projects in good economic times, when the commodity price was in a more profitable range, Petrobras decided to conduct a study of optimizing the collaborative environment of its drilling centers. Study elements included understanding the value of the drilling centers, identifying improvements, and assessing the four key elements of IO: people, process, technology, and organization. There is clearly opportunity to rethink collaborative environments to better meet the work practices of the next generation [4]. However, the question specific to drilling centers is, “What are those opportunities?” To answer this question, Petrobras conducted an intensive survey between September 21 and November 30, 2015, of all the employees at its drilling centers, including both the operational and specialized workforce. Petrobras drilling centers are distributed regionally, in alignment with operating areas. However, the study was also intended to promote corporate integration of these collaborative environments, which can be classified by their activity as operational and expert drilling centers.

Beyond the specific findings for Petrobras, the study establishes a methodological approach that is applicable across the oil industry, not just for drilling centers. The applicability and scalability of this methodology are reinforced by inclusion of statistical analysis of the questionnaire responses.

This article begins by setting the context for IO and the concept of drilling centers, followed by a description of the collaborative environments for well construction at the Petrobras drilling centers. The research methodology used is presented next. The “Results and Discussion” section reviews the statistical analysis of the survey results and how those findings were applied at Petrobras with demonstrated value. One result is implementation of an integrated expert drilling center as an advanced work environment, called the Hub, which is staffed by experts from several disciplines who collaborate on critical operational processes with the common objective of optimizing drilling performance and productivity. This is consistent with Maliardi and Renzo [5], with the benefit analysis based on business cases.

Integrated Operations are based on the integration concept of people, processes, technology and organization to result in better and more effective operational decisions. IO is a collaborative approach, which involves right-time data, technologies, and multidisciplinary processes [6]. Edwards et al. [7] explained that IO initiatives are founded on four pillars: process, people, technology, and organization, called the PPTO approach. The four key elements must work together, usually supported by collaborative work environments, to improve business value, cost reduction, and safety. According to Henderson et al. [8], the four key elements must be present as follows: (1) Process: the core work processes must be identified for improvement to deliver new value; (2) People: all skills, competencies, and behaviors that are needed to execute processes must be involved in the change management process through coaching or training; (3) Technology: the technologies necessary to share information and communicate collaboratively must be available or established; and (4) Organization: organizational structures and relationships must be in place to realize added value. Today, most oil and gas companies have established this type of IO programs [9].

In recent years, Petrobras has also used the IO approach. The first implementation was in production operations and focused on some enterprise solutions. According to Lima et al. [10], these solutions were deployed following three steps: (1) Standardization: definition of the standards of business process, systems and tools that can influence the asset optimization; (2) Scalability: use of an information technology architecture compatible across the organization; and (3) Sustainability: implementation of the solutions by using robust methodologies to avoid obsolescence. These steps provided better information integration in Petrobras, enabling large increase in the efficiency of the organization. This IO implementation in Petrobras was an E&P initiative, based on the articulation of technical disciplines and suppliers involved in operational activities and focused on proactive actions to improve quality and introduce a larger vision to operational planning. According Pereira et al. [11], IO is more than a program for restructuring and improving operational processes. It is a new work philosophy, having as a central pillar the integration of E&P processes. This is being implemented in all Petrobras operational units, at different maturity levels. The main projects are oil and natural gas production and processing, integrated planning and logistics, supply operations, drilling and workover operations, subsea installations, and E&P operations.

Drilling centers have a number of software technologies and hardware solutions that integrate information to support the work processes conducted by the onshore teams. According Thorsenm et al. [12], the onshore team uses real-time data to focus on proactive processes to ensure overall operational progress in the safest way. Herbert et al. [13] noted that the drilling centers have multidisciplinary teams working 24/7, using technologies for analysis and support operations, equipment, and processes. According to Booth [14], it is possible to separate the history of drilling centers into two generations. The first generation had a short life and could not survive because of low commodity prices at the end of the 1980s. The second generation benefited from the rapid evolution of information technology at the beginning of the 2000s and grew in line with E&P IO initiatives. It is noteworthy that prior to these IO initiatives, Petrobras had successful drilling center implementations [15] that can be considered within Booth’s second generation.

There are many practical cases around the world proving value to IO implementations. Bogaert et al. [16] presented benefits on average of 10% in production and about 2% in additional reserves in Shell, considering the application of smart technologies. The authors also described a gain of 6 to 7% from gas lift optimization. According to Edwards et al. [7], 0.5 to 2.0% production increase in IO projects can represent impressive value gain. Benefits of around 6 million of dollars/month were described by a case study review in Brulé et al. [17], who studied the economic impact in the decision making time caused by inadequate integration. Kapteijn [18] illustrated the importance of IO projects in the value creation and pointed more than 10% of improvement in Shell fields’ production by using IO initiatives. Thorogood et al. [19] described a case of integrated services in North Sea, where the optimization of the waste disposal represented 2 million dollars in savings. Crawford et al. [20] described impressive results of an assessment in ExxonMobil production surveillance, pointing that around 44% of the work time was dedicated to generate reports and access data. Benefits on recovery increase (5 to 10%), production improvement (10%), cost reduction (20%) and risk mitigation were pointed by Henderson et al. [8], considering the applications of IO technologies. Moore-Cernoch [21] presented important cases of British Petroleum collaborative operating centers.

Some of the drilling center benefits presented in Maliardi and Renzo [5], although not quantified, are (1) improvement of HSE aspects; (2) early detection of potential well problems; (3) enhancement of drilling efficiency with controlled cost; (4) improvement of wells placement, quality, and productivity; (5) better leverage of the most experienced drilling personnel population at a global level; (6) creation of a multidisciplinary work environment for more-effective decision-making; and (7) the possibility to improve and accelerate personnel training and competency by providing a comprehensive vision of operations through exposure to a variety of pertinent activities at the same time.

2. PETROBRAS DRILLING CENTERS

The Petrobras Drilling Centers are designed to provide technical support for operational decision making at rigs during drilling, completion, or workover operations. Petrobras has seven drilling centers, geographically located in different regions. As a graphical representation, (Fig. 1) shows the layered architecture. From the core outward, it is possible to find data and information that are provided to all other spheres. The first, innermost layer is formed by expert teams in which experts work in two separate physical environments. One team is focused on rig performance and operational safety and uses data transmission tools and images in real time. In another environment, other experts mainly within technical disciplines assist in building offshore wells, such as providing special services, cementing, completion, and evaluation. In the subsequent layers, there are the drilling operation centers, with experts who are responsible for construction of the wells and support staff in company offices. Finally, there is the outside layer of rigs, representing the offshore units and their operations. According to Kasumov et al. [22], the success provided by this concept comes from the combination of several technical and expert groups within the operator and service companies to address challenges throughout well project execution. Fig. (1) gives a general idea of the Petrobras drilling centers in this context.

|

Fig. (1). Petrobras drilling centers in the context of well construction. |

The Petrobras drilling centers are supported by solutions that can be classified into five groups, as follows: (1) project data solutions for creating and editing well projects and long-term resources schedules, such as for boats and rigs, which are critical resources for these E&P activities; (2) operational data and key performance indicator (KPI) solutions for capturing and reporting operational status data, registering the building of wells and maintenance life cycle and resource use, and recording rig indicators’ informational solutions, lost time, cost, quality indicators, operations safety data, and rig and blowout preventer (BOP) specifications; (3) real-time data solutions for transmitting data acquired offshore to shore because it is real-time data that supports most of the systems used in drilling centers; (4) operational images solutions that consist of a software and hardware set that perform the collection and transmission of camera images from the rig to the drilling centers as an assist in decision making; and (5) video conferencing solutions with voice and image integration that enable people offshore to connect with the drilling centers and other onshore environments toward assisting in decision making. Table 1 shows the main activities of a typical drilling center.

| Surveillance | Safety | Performance Analysis | Training |

|---|---|---|---|

| • Drilling parameters analysis, directional data and well trajectory • Well stimulation operation • Logging while drilling • Geosteering • Formation evaluation • Pore pressure and well fractures • Evaluation testing • Physical and chemical parameters of fluids and stimulation • Well diagnosis |

• Safety barriers management • Well safety • Emergency response • Dynamic positioning • Test monitoring and simulations • Operations and integrity |

• Drilling parameters optimization • Drilling fluid physical and chemical properties optimization • Lost time reduction • Well construction process performance analysis |

• Well execution and maintenance • Geological monitoring evaluation |

3. METHODOLOGY

The methodological approach implemented in this study was based on a literature review to find applications, cases and strategies of IO and drilling center initiatives across oil operators. The methodological framework is presented in the Fig. (2). Four scientific bases were used: the OnePetro, Springer, Elsevier and Scopus online collections of scientific and technical documents. Search of the databases was based on the keywords integrated operations, drilling centers, and collaborative work environment. The final result is the reference list of this article.

|

Fig. (2). Methodological approach. |

In consonance with Kuhn [4], today there is a clear opportunity to rethink collaboration environments to better meet the work practices of next generation. An internal survey was conducted by Petrobras covering the dimensions of people, process, technology, and organization (PPTO). The methodological approach of this research was based on the literature review presented by Lima et al. [23], which analyzed IO initiatives in the major oil companies. The research tool used the Likert scale [24] ranging from 1 to 5: strongly disagree, disagree largely, indifferent, largely agree, and totally agree. The questionnaire concept was based on clusters of questions pertaining to each of the PPTO components as presented in Table 2.

| DIMENSION CLUSTER | MAIN QUESTIONS |

|---|---|

| People | The drilling center enables collaboration with teams at other drilling centers, rigs, and the administrative staff so that people discuss ideas and exchange experiences and best practices [25]. |

| The drilling center operational decisions involve the necessary experts, even if they are acting remotely or virtually [26]. | |

| The work at the drilling center involves trained people with the proper competence [27]. | |

| The decisions of drilling center teams are taken in a proper and consistent and timing compared with the operational reality because people have autonomy for decision making [28]. | |

| The drilling center works in a cooperative and integrated way, enabling an organizational culture based on scenario analysis and decision-making support [27]. | |

| Process | The drilling center working processes are properly automated in that the already include all tasks that can be automated [29]. |

| The processes are properly optimized, designed, and standardized by incorporating best practices, aligning to the company goals, and bringing value to the business [26]. | |

| The interfaces between processes of the drilling center and other decision centers and rigs are well defined and clear [30]. | |

| The drilling center work processes are properly supported by data and information, which are available at the right time [31]. | |

| All tasks possible are already transferred to the drilling centers and the tasks that are executed in the rigs are only activities that cannot be performed onshore [24]. | |

| Technology | Connectivity (bandwidth and latency) is compatible (reliable, redundant, and efficient) with the activities of the drilling center [26]. |

| The drilling center has a proper physical environment for the processes (environment automation, visualization systems, lighting, furnishings, air conditioning, and sound system) [27]. | |

| The software solutions available in the drilling center (simulators, systems, and engineering tools) are sufficient and accessible [32]. | |

| The data and information of the drilling center processes are readily available for correct interpretation and understanding [25]. | |

| Hardware technologies (computers, i-board, videoconferencing, telepresence) are available, sufficient, accessible, and easy to use [30]. | |

| Organization | Your work is important to the organization [33]. |

| The drilling center relationship with other managers is properly established [26]. | |

| The drilling center objectives are aligned with the organization’s goals [32]. | |

| The drilling center is important in value creation for process customers and Petrobras [34]. | |

| The E&P organizational structure is compatible with the drilling centers [34]. |

An internal tool, based on the corporate intranet, was used to perform this research. The solution is an integrated system client-server, within the company’s e-mail solution. This system manages any type of search since its creation, consisting of three basic forms: search form, question form, and the form sent to the participants. Thus, the online survey was automatically applied to all interviewees. The online survey was conducted between September 21 and November 30, 2015, and a total of 131 forms were submitted, covering all professionals working locally in the Petrobras drilling centers. Kaplowitz et al. [35] emphasized that a survey sent through the internet can reach a significant number of people who fill out forms in comparison with printed questionnaires if it is preceded by an email notification. The survey was concluded with 71% of respondents, well above that of Marconi and Lakatos [36], who explain that, on average; the questionnaires sent by Internet reach a 25% response. The higher value of the response rate was achieved with reinforcement conducted every two weeks for those who had not answered. This approach included professionals who worked in shifts. Finally, the Kruskal-Wallis test [37] was used to analyze the survey differences among the PPTO clusters and among the responses of the expert and operational drilling centers.

Table 3 summarizes the hypotheses tested in this research, as to whether there was differentiation of the expert and operational drilling center groups of respondents.

| Hypothesis | Description |

| 1 | There is no difference in the evaluations with regard to the different PPTO dimensions (clusters) analyzed. |

| 2 | There is no difference in the evaluation between expert and operating groups considering the different PPTO dimensions (clusters) analyzed. |

4. RESULTS AND DISCUSSION

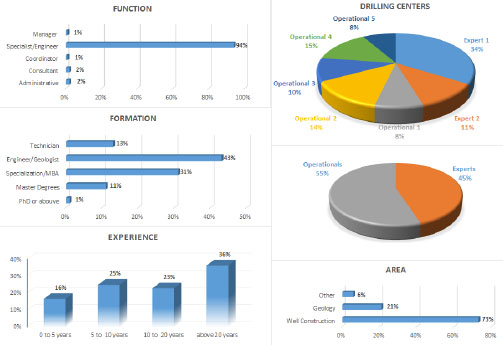

In Section Two, it was explained that during drilling, completion, or workover operations the Petrobras Drilling Centers provide technical support for operational decision making at rigs. These support are from multidisciplinary teams working 24/7, using different technologies, equipment and process. In this way, to better understand the maturity of these environments, geographically located in different regions, the survey was sent to all workers in the Petrobras drilling centers. Fig. (3) shows that almost all of them are specialists and engineers (94%), with postgraduate degrees and seniority (only 16% were early in their career). The population was well divided between the two expert and five operational drilling centers. The majority of the respondents (73%) are dedicated to well construction. Statistical analysis was applied to the results to support the application of this methodology to other oil industry scenarios and to understand the scalability of this study to other companies.

|

Fig. (3). Profile of survey respondents. |

Table 4 presents the descriptive statistics of the survey evaluation. The analysis is organized based on the question clusters (people, process, technology, and organization).

| Cluster | Average | Std Deviation | Min | 1º Quartile | Median | 3º Quartile | Max |

| People | 4.48 | 0.39 | 3.60 | 4.20 | 4.60 | 4.80 | 5.00 |

| Process | 3.79 | 0.64 | 2.20 | 3.40 | 3.80 | 4.20 | 5.00 |

| Technology | 3.90 | 0.70 | 2.00 | 3.40 | 4.00 | 4.40 | 5.00 |

| Organization | 4.61 | 0.37 | 3.20 | 4.40 | 4.60 | 5.00 | 5.00 |

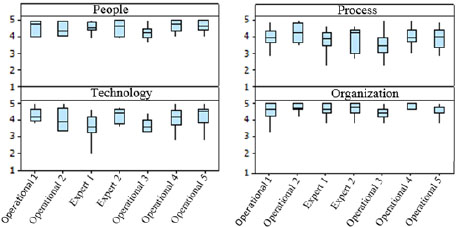

Considering the average and median of the evaluations, it is concluded that the respondents’ perception is that the people and organization clusters perform better than the other two, process and technology. The general distribution of the evaluations for the clusters is well depicted by the box plot in Fig. (4).

|

Fig. (4). Clusters box plot. |

The nonparametric Kruskal-Wallis test [37] was used to check for statistically significant differences among the clusters. The p-value of this statistical test was less than 0.001, indicating that hypothesis 1 of equality in Table 3 for the evaluation of the clusters should be rejected. The results of this test also show that the organization and people clusters have statistically higher evaluations than those of the process and technology clusters. Table 5 consolidates the results.

| Cluster | Kruskal-Wallis Median | Mann-Whitney Test pValue | Cronbach’s Alpha |

|---|---|---|---|

| p-value < 0.001 | Operational × Expert | ||

| People | 4.6 | 0.60 | 0.6119 |

| Process | 3.8 | 0.71 | 0.7624 |

| Technology | 4.0 | 0.10 | 0.7744 |

| Organization | 4.6 | 0.47 | 0.6918 |

| Kruskal-Wallis test results for cluster evaluations | Mann-Whitney test results for operational and expert drilling centers | Cronbach’s alpha coefficient for the PPTO clusters |

As explained in the preceding section on the Petrobras drilling centers, the drilling centers were classified considering their activity as either operational (i.e., the drilling center is dedicated to monitoring, follow up, and control of well construction operations) or expert (i.e., the drilling center works with specialists across several areas for all the fleet rigs). A nonparametric Mann-Whitney test analysis [37] was used to compare the perceptions of the different groups. Table 5 summarizes the result of the statistical test and indicates that there is no statistically significant difference between the operational and expert groups in any of the clusters analyzed.

A new ordering of the results with reference to the assessment of the drilling centers was made to obtain a more detailed analysis of the results of each cluster. The expert drilling center 01 and operational drilling center 03 have a worse evaluation for the technology cluster. For the process cluster, operational drilling center 01, expert drilling center 01, and operational drilling center 03 have the worst results. The other clusters for people and organization have more homogeneous and higher evaluations, as illustrated in Fig. (5).

|

Fig. (5). Drilling centers box plot. |

The internal consistency of the questionnaires was assessed using Cronbach’s alpha [38]. The Cronbach’s alpha coefficient is a commonly used as a measure of reliability (e.g., it is an assessment of the internal consistency of questionnaires) for a set of two or more construct indicators. The values range from 0 to 1. The closer to 1, the higher the reliability among the indicators. Cronbach’s alpha coefficient was applied to the clusters, as shown in Table 5. The coefficient’s reasonable value expressed a good interrelation between questions. Thus, Cronbach's alpha coefficient reflects good consistency and interrelationship among the questions.

The statistical tests were important for verifying the hypotheses in Table 3. The rejection of the hypothesis of equality on the evaluation of the different clusters validates the projects for people and technology that Petrobras is implementing for its drilling centers, as subsequently discussed in this article. The second hypothesis tested, which showed that there is no statistically significant difference between the operational and expert groups, indicates that the initiatives should be applied to all drilling centers. The results of the statistical tests are summarized in Table 6.

| Hypothesis | Result | Description |

|---|---|---|

| 1 | Rejected | p-value < 0.001. The hypotheses of equality for the evaluation of the different clusters should be rejected. |

| 2 | Not rejected | p-value > 0.001. There is no statistically significant difference between the operational and expert groups in any of the clusters analyzed. |

4.1. Hub Implementation

Of the IO key elements studied in the survey, process and technology were rated lower. To improve rig performance and the operational and service processes, Petrobras decided to integrate the expert drilling centers in a unique collaborative Hub environment that would facilitate continuous improvement while increasing operational efficiency, reducing time, and enhancing safety. The processes of both specialist areas were analyzed to identify areas for better integration, which in turn would yield greater benefits for the company. The project was divided into five phases, as shown in Fig. (6). The three first phases are related to the project design.

|

Fig. (6). Project phases. |

For each phase of the project, the following products were defined: initiative structuring with the overview and definitions context of the drilling centers integration (Phase 1); definition of the conceptual model with delimitation of the integration of the expert drilling center and preliminary studies of processes, benefits, and conceptual layout of the collaborative environment (Phase 2); analysis of the expert drilling center processes for the identification of integration benefits and final layout setup of the collaborative environment to define necessary infrastructure (Phase 3); implementation of collaborative environments and communication protocols across the drilling centers (Phase 4); and management and process standards (Phase 5).

4.2. Hub Benefits

During Phases 2 and 3, when the expert drilling centers were still physically separate, some processes from both of the expert drilling centers were mapped and studied to understand possible gains of the integrated collaborative environment. This benefits pilot was important to the economic technical analysis of the project. Operating time optimization was the key element verified. A good example is the casing run. The process redesign involved information prior the operation, the well construction schedule, the companies involved in the procedures, and the list of best practices for performing analysis of the casing and cement operation. At the end, an action plan was proposed, which had positive impacts on both the safety and performance aspects of reliability. As the plan was implemented by the experts at the Hub, it was observed that the actions contributed to a 7.25% decrease in time required for a casing run. Thus, improvement in the ergonomic and technological conditions of the integrated drilling center environment facilitated the propagation of lessons learned through a growing number of collaborative operations. Because the drilling centers play a fundamental role in the integrated monitoring of operations, the study shows a potential gain from discipline integration: working together will result in lower operating time and, consequently, less costly operations. It is important to note that the value estimate was possible only for operations that are monitored in real time by using the Hub integrated systems environment. However, additional gradual improvement from implementing new processes is also possible. Considering the estimated investment for the Hub integration and the gains from this pilot, the estimated time to payback is about 4 months, which makes it a very attractive project.

CONCLUSION

The study of IO processes for the PPTO dimensions related to offshore well construction collaborative environments at Petrobras drilling centers showed the evolution of the study respondents’ perspective of these environments. The results rated the people and organization dimensions higher. The process and technology clusters were also well evaluated, but not as highly rated as people and organization. The results of this research allowed Petrobras to improve rig performance and the operational and service processes. Petrobras integrated the expert drilling centers in a unique collaborative environment. The Hub was operationalized and brought positive impacts on safety and performance in the well construction. The improvement in the ergonomic and technological conditions of the integrated drilling center environments will result in lower operating time and less costly operations. For an example, it was observed a 7.25% decrease in time required for a casing run. Although the implementation of initiatives can be guided by these results, the company will not ignore human factors, which represent the greatest asset of the organization.

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

The authors wish to thank Petrobras for the permission to publish this paper. We also acknowledge the support of Federal Fluminense University.